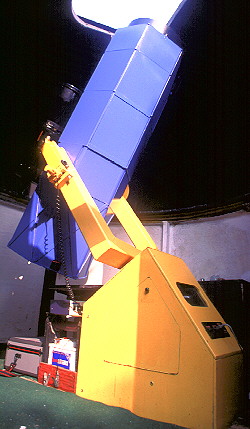

Finished Telescope on the fork mount

Introduction

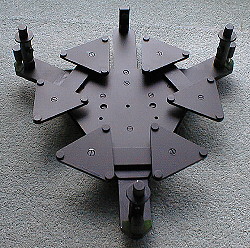

This telescope, originally known as Stealth, is a team effort. The tube assembly is an aluminium frame constructed by Gerald, the mount by myself and the optics by Brian. The stealth name comes from its attempt to cut out light reflections. Rather than the more usual Surrurier truss tube, which is more suitable for dark skies, a design using diaphragms was adopted. Diaphragms or baffles provide the best weapon against light pollution. The central aperture in each baffle increases away from the mirror and matches the field of view of the telescope. In this design the baffles also act as structural elements along with 6 x 50mm aluminium tubes. Shown below the structure of the telescope is clearly visible but on the finished telescope (left), plastic panels have enclosed the tube masking the construction.